Partager la publication "McLaren F1 : châssis carbone, design aéro-dynamique, moteur BMW M Power V12. 627 ch."

McLaren F1 est la première automobile a permettre au pilote d’être en position centrale. Le 31 mars 1998, la McLaren F1 devient la voiture de série la plus rapide au monde avec une vitesse de pointe officielle de 386,7 km/h établie sur le terrain d’essais Volkswagen de Ehra-Lessien, en Allemagne. Ce titre a tenu jusqu’à l’arrivée de la Koenigsegg CCR de 800 ch en 2005, et de la Bugatti Veyron 16.4 de 1 200 ch quelques mois plus tard. Cependant, la McLaren F1 garde le record pour une automobile à moteur atmosphérique, et le moteur ne fait que 600 ch. La McLaren c’est l’automobile d’une génération. Ma génération c’est celle des années 1990. La génération qui a connu les premiers jeu vidéo Need for Speed. C’est sûrement là que toute une génération a découvert cette automobile fascinante. Mais ce qui est encore plus fascinant, c’est le parcours d’un entrepreneur, d’un engineer et d’un designer. Tous les trois et tous du team McLaren ont créé l’ultime road-car. Ever. Forever.

McLaren F1

Lire le post dédié aux début et parcours de Ron Dennis, Gordon Murray, Peter Stevens, et le projet McLaren F1

==> McLaren F1 : le projet ultime by McLaren Cars. Moteur BMW V12. L’héritage de la génération 90.

‘Power, pace and peerless quality, the legendary McLaren F1 is a technological masterpiece. The fastest production car of its time. The finest sports car of its generation. For many, the greatest supercar ever built.’

‘Brilliance takes time. It took four years to meticulously plan, design and build the all-conquering F1. Beautifully engineered and exceptionally quick, the F1 broke numerous world records during the ‘90s, and it remains the fastest naturally aspirated road car ever built. Only 106 cars were made in a limited production run, making the F1 one of the most exclusive cars in the world today.’

- McLaren Cars

Le châssis de la McLaren F1

Chief engineer Gordon Murray’s design concept was a common one among designers of high-performance cars: low weight and high power. This was achieved through use of high-tech and expensive materials such as carbon fibre, titanium, gold, magnesium and kevlar. The F1 was the first production car to use a carbon-fibre monocoque chassis.

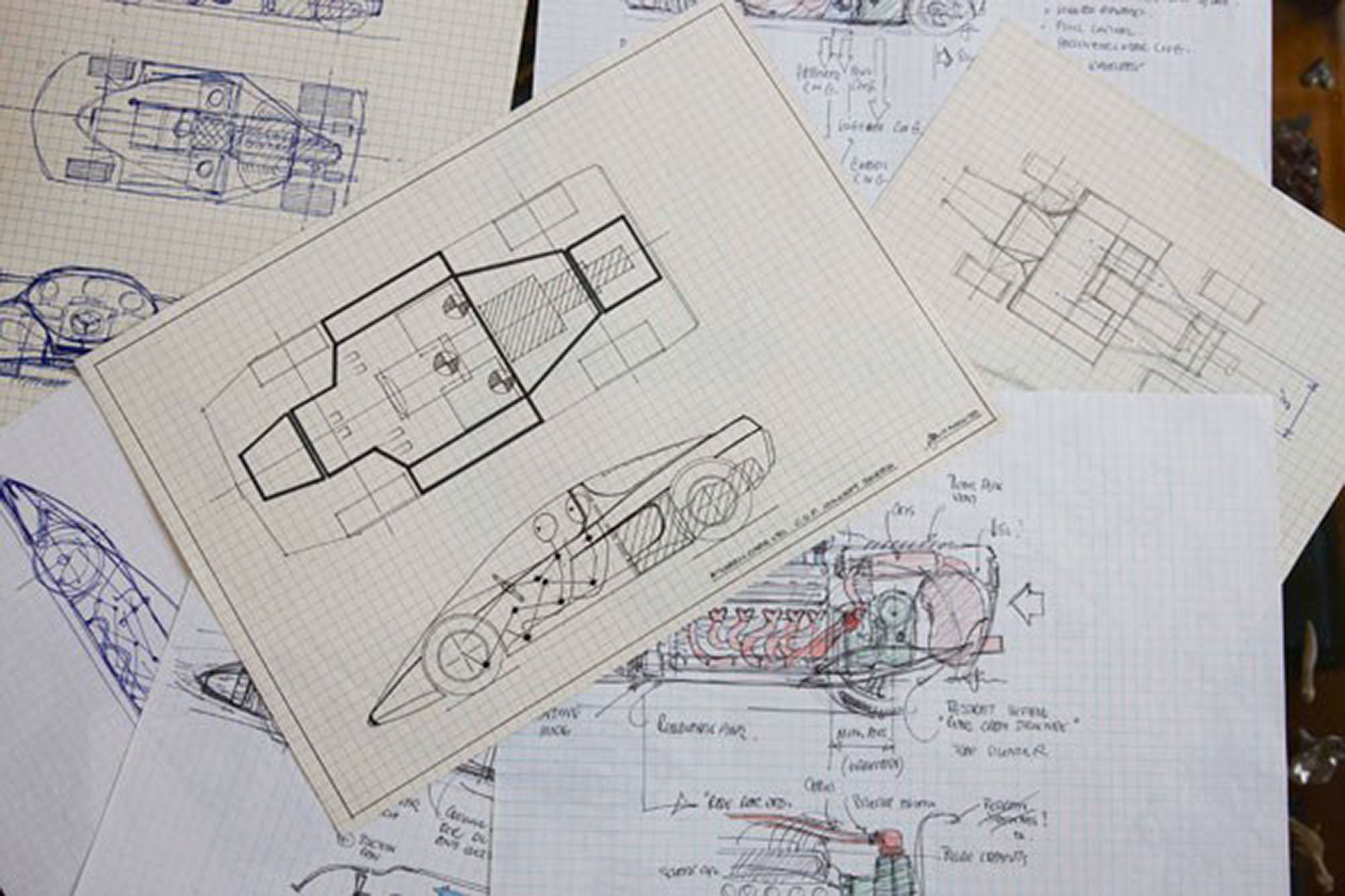

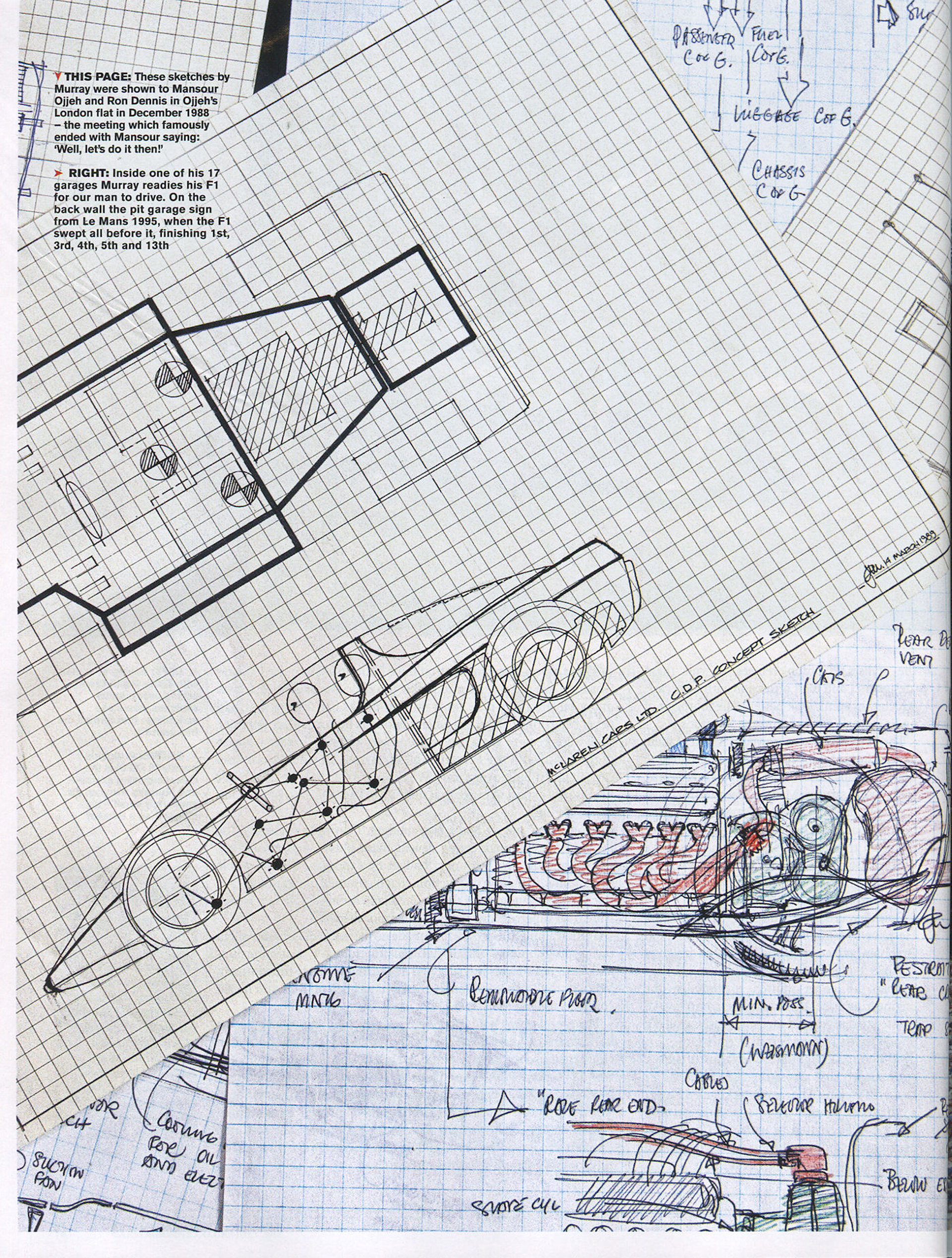

McLaren F1 – blueprint

‘After analysing existing supercar performance characteristics, the F1’s handpicked engineering team rethought every element of sports car design. Drawing on McLaren’s Formula 1 expertise, and with an uncompromising approach to design, they stripped weight, reduced drag and increased downforce. Every millimetre of the F1 was deliberated to create the world’s most exhilarating car.’ - McLaren Cars

Gordon Murray exploite de très nombreuses technologies et techniques utilisées en Formule 1. On ne change pas une technologie qui gagne.

Pour les matériaux, Murray ne se refuse rien : la coque sera intégralement réalisée en fibre de carbone, une technique alors encore jamais utilisée dans l’automobile. Ainsi, l’ensemble monocoque châssis-carrosserie est intégralement en composite. La structure se compose d’éléments moulés, soit sous forme mixe carbone-NIDA-carbone, soit en simples panneaux de fibres de carbone, unidirectionnelles ou tissées, selon les besoins.

La coque est encadrée par des solides longerons et des massifs caissons latéraux enveloppant les sièges des passagers. L’ensemble de cette structure est une véritable cellule de survie à la manière d’une coque de Formule 1 moderne.

The McLaren F1 was the first production road car to use a complete carbon fibre reinforced polymer (CFRP) monocoque chassis structure. Aluminium and magnesium were used for attachment points for the suspension system, inserted directly into the CFRP.

The engine produces high temperatures under full application and thus causes a high temperature variation in the engine bay from no operation to normal and full operation. CFRP becomes mechanically stressed over time from high heat transfer effects and thus the engine bay was not constructed from CFRP.

To enhance performance, handling, braking and sheer driving feel, the F1 team knew they would have to minimise weight – everywhere. Lighter and stronger than aluminium, the F1 was the first road car with a carbon fibre chassis. Its weight-saving wheels were made from magnesium alloy. The supporting sub-structure was made from titanium. Even the toolkit, made from titanium, was 50% lighter than a steel kit. - McLaren Cars

La direction à crémaillère passe dans un tunnel central en magnésium sur lequel se fixent les attaches des suspensions. L’habitacle est très particulier, avec 3 places de fronts, avec le conducteur au centre avancé vers l’avant, et les deux passagers de chaque côté en retrait. Cette disposition particulière des sièges permet aussi de réduire la largeur de la voiture.

The car features a central driving position – the driver’s seat is located in the middle, ahead of the fuel tank and ahead of the engine, with a passenger seat slightly behind and on each side.

McLaren F1 – blueprint engine

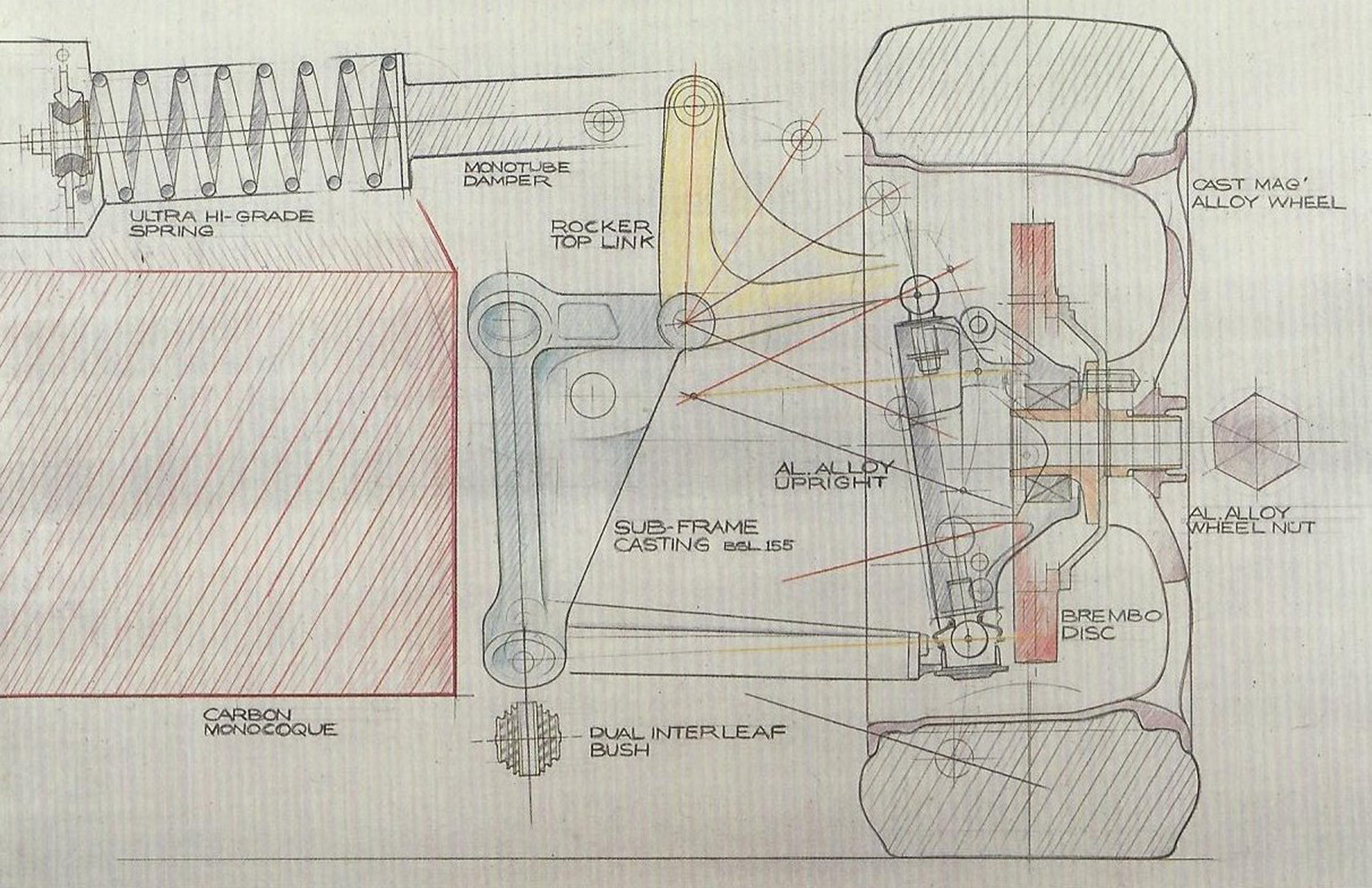

Steve Randle, who was the car’s dynamicist, was appointed responsible for the design of the suspension system of the McLaren F1 machine.

It was decided that the ride should be comfortable yet performance-oriented, but not as stiff and low as that of a true track machine, as that would imply reduction in practical use and comfort as well as increasing noise and vibration, which would be a contradictory design choice in relation to the former set premise – the goal of creating the ultimate road car.

From inception, the design of the F1 vehicle had strong focus on centring the mass of the car as near the middle as possible by extensive manipulation of placement of, inter alia, the engine, fuel and driver, allowing for a low polar moment of inertia in yaw. The F1 has 42% of its weight at the front and 58% at the rear, this figure changes less than 1% with the fuel load.

The distance between the mass centroid of the car and the suspension roll centre were designed to be the same front and rear to avoid unwanted weight transfer effects. Computer controlled dynamic suspension were considered but not applied due to the inherent increase in weight, increased complexity and loss of predictability of the vehicle.

The suspension is a double wishbone system with an unusual design. Longitudinal wheel compliance is included without loss of wheel control, which allows the wheel to travel backwards when it hits a bump – increasing the comfort of the ride.

Castor angle wind-off at the front during braking is handled by McLaren’s proprietary Ground Plane Shear Centre – the wishbones on either side in the subframe are fixed in rigid plane bearings and connected to the body by four independent bushes which are 25 times more stiff radially than axially. This solution provides for a castor wind-off measured to 1.02 degrees per g of braking deceleration. Compare the Honda NSX at 2.91 degrees per g, the Porsche 928 S at 3.60 degrees per g and the Jaguar XJ6 at 4.30 degrees per g respectively. The difference in toe and camber values are also of very small under lateral force application. Inclined Shear Axis is used at the rear of the machine provides measurements of 0.04 degrees per g of change in toe-in under braking and 0.08 degrees per g of toe-out under traction.

When developing the suspension system the facility of electro-hydraulic kinematics and compliance at Anthony Best Dynamics was employed to measure the performance of the suspension on a Jaguar XJR16, a Porsche 928S and a Honda NSX to use as references.

McLaren F1 – sketch – suspension

McLaren F1 brakes by Brembo

The F1 features unassisted, vented and cross-drilled brake discs made by Brembo. Front size is 332 mm (13.1 in) and at the rear 305 mm (12.0 in).

The calipers are all four-pot, opposed piston types, and are made of aluminium. The rear brake calipers do not feature any handbrake functionality, however there is a mechanically actuated, fist-type caliper which is computer controlled and thus serves as a handbrake.

Gordon Murray attempted to utilise carbon brakes for the F1, but found the technology not mature enough at the time; with one of the major culprits being that of a proportional relationship between brake disc temperature and friction—i.e. stopping power—thus resulting in relatively poor brake performance without an initial warm-up of the brakes before use. (Since carbon brakes have a more simplified application envelope in pure racing environments, this allows for the racing edition of the machine, the F1 GTR, to feature ceramic carbon brakes.)

McLaren F1 tyres by Goodyear & Michelin

The McLaren F1 uses 235/45ZR17 front tyres and 315/45ZR17 rear tyres.

These are specially designed and developed solely for the McLaren F1 by Goodyear and Michelin. The tyres are mounted on 17-by-9-inch (430 mm × 230 mm) front, and 17-by-11.5-inch (430 mm × 290 mm) rear five-spoke cast magnesium wheels, coated with a protective paint and secured by magnesium retention pins.

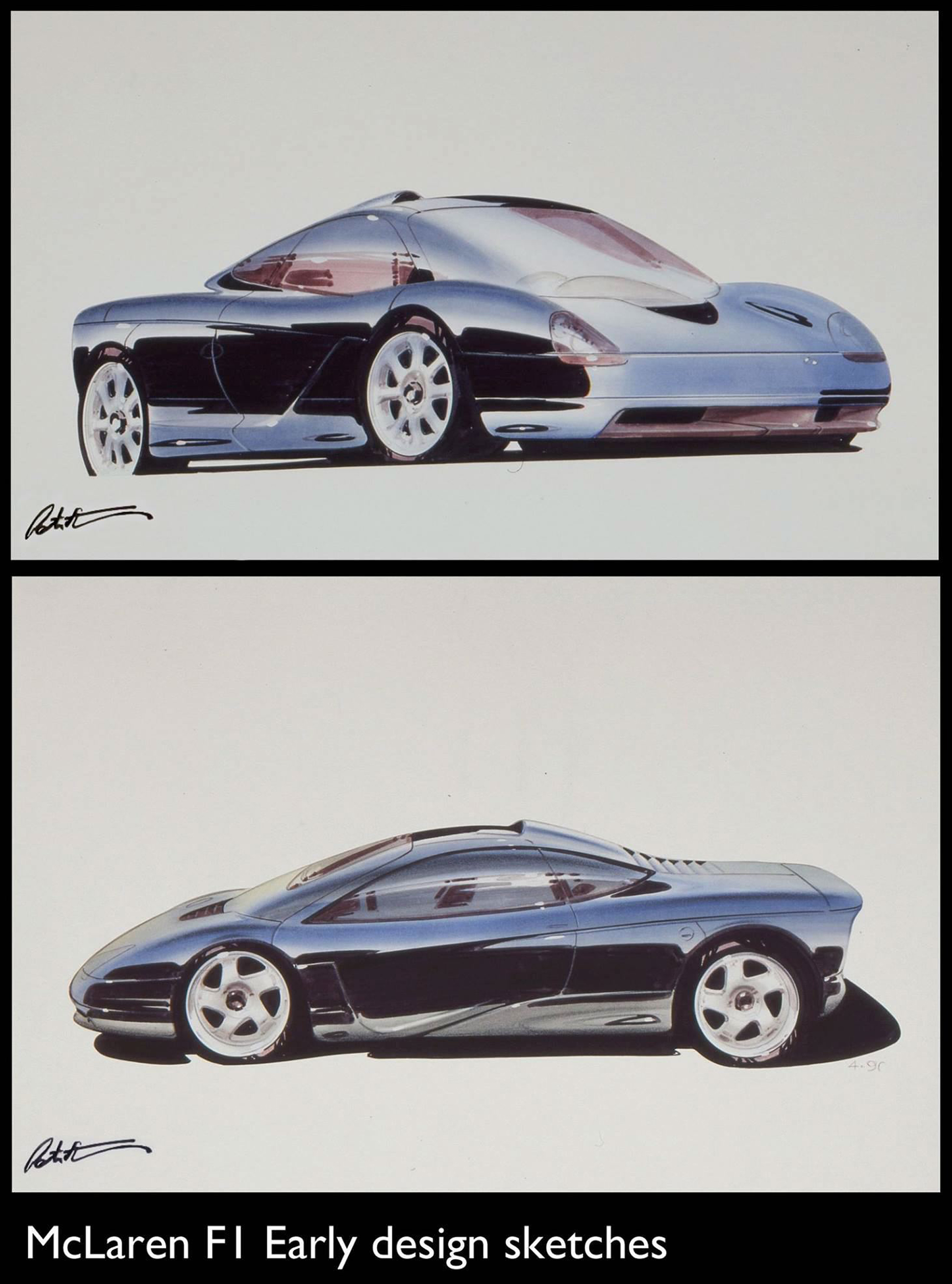

Le design de la McLaren F1

McLaren F1 – design sketch by Peters Stevens

McLaren F1 – designer Peter Stevens

‘The F1’s chief designer, Gordon Murray, had been working on a one-plus-two seating configuration since 1969. Twenty years later, his innovative arrowhead concept came to fruition in the F1.’

‘No spoilers. No wings on struts. Absolute stability at high speed. These were the immutable aerodynamic principles the F1 was designed on. To create traction-enhancing load without adding mass, the team also applied the latest ground force techniques to the car.’

- McLaren Cars

McLaren F1 – aerodynamic

L’aérodynamique « a fait équipe » pour créer le design de la McLaren F1. Très tôt dans l’élaboration de la voiture, les études en souffleries ont été menées et ont été décisives dans le dessin de Stevens. Pas moins de 1 130 séances en souffleries ont été passées à étudier et déterminer les appuis et lignes de la McLaren F1.

Le résultat est tout bonnement exceptionnel car sans aucun artifice aérodynamique, la McLaren F1 peut rouler très vite et générer de l’appui. En effet, tout le travail de l’équipe a consisté à lutter contre la portance à grande vitesse, et aussi à déterminer l’emplacement idéal pour le centre de poussée, qui est le point où convergent les forces aérodynamiques agissant sur le véhicule.

The overall drag coefficient on the standard McLaren F1 is 0.32, compared with 0.36 for the faster Bugatti Veyron.

The normal McLaren F1 features no wings to produce downforce (compare the LM and GTR editions) however, the overall design of the underbody of the McLaren F1 in addition to a rear diffuser exploits ground effect to improve downforce which is increased through the use of two electric Kevlar fans to further decrease the pressure under the car.

A « high downforce mode » can be turned on and off by the driver.

At the top of the vehicle, there is an air intake to direct high pressure air to the engine with a low pressure exit point at the top of the very rear.

The doors on the vehicle move up and out when opened, and are thus of the butterfly type. Under each door is a small air intake to provide cooling for the oil tank and some of the electronics.

McLaren F1 – front side-face / profil avant – open doors / portes ouvertes

‘The dihedral doors are an elegant solution to a complex problem. Beautiful, simple, practical, their wide opening design makes it easy to access the central driving position.’ - McLaren Cars

The airflow created by the electric fans not only increases downforce, but the airflow that is created is further exploited through design, by being directed through the engine bay to provide additional cooling for the engine and the ECU. At the front, there are ducts assisted by a Kevlar electric suction fan for cooling of the front brakes.

There is a small dynamic rear spoiler on the tail of the vehicle, which will adjust dynamically and automatically attempt to balance the centre of gravity of the car under braking – which will be shifted forward when the brakes are applied. Upon activation of the spoiler, a high pressure zone is created in front of the flap, and this high pressure zone is exploited — two air intakes are revealed upon application that will allow the high pressure airflow to enter ducts that route air to aid in cooling the rear brakes.

The dynamic rear spoiler increases the overall drag coefficient from 0.32 to 0.39 and is activated at speeds equal to or above 40 mph (64 km/h) by brake line pressure.

Le moteur de la McLaren F1

“The F1 was born with three goals. One was to solve the problems inherent in most supercars: bad seating position, lack of visibility, terrible pedal offsets, no space to carry stuff in the cabin, poor luggage space, no decent sound system or air conditioning.

“Another was to enhance the driver’s experience. It seemed to me supercar design was being dictated by performance figures, whereas building a really great driver’s car is a much more emotional thing than figures on paper. We knew the F1 would be fast because it would be small and light, but we didn’t dwell on that.

“My original notes called for a V10 or V12 of about 450bhp; it wasn’t until my pal Paul Rosche, BMW’s top engine expert, proposed a very compact 6.0-litre V12 that we knew it would be as quick as it was.

“The third thing was to make the most of the central driving position – to really focus on giving owners the best possible driver experience. The F1’s layout allowed us to concentrate absolutely on driver location and comfort, and it worked. We found you could move the driver about a foot forward and give him a very low cowl that gave great vision.

“You could also hide all the stray bits and pieces – washer bottle, ventilation system and even air vents – in the nose so you were left with a pure, fighter-style cockpit, something owners still love.”

“We’d looked at the Lamborghini Countach and the Jaguar XJ220 and knew we didn’t want anything like that.”

- Gordon Murray

Gordon Murray veut absolument un moteur atmosphérique, avant tout pour des raisons de sonorité et de réactivité à l’accélérateur, à une époque où le fameux ‘turbo lag’ pose encore de réels problèmes.

Gordon Murray insisted that the engine for this car be naturally aspirated to increase reliability and driver control. Turbochargers and superchargers increase power but they increase complexity and can decrease reliability as well as introducing an additional aspect of latency and loss of feedback. The ability of the driver to maintain maximum control of the engine is thus compromised.

Murray exige au moins 550 chevaux et un bloc moteur compact : 600 mm de longueur et 250 kilos maxi.

Murray initially approached Honda for a powerplant with 550 bhp (410 kW, 558 PS, 558 ch), 600 mm (23.6 in) block length and a total weight of 250 kg (551 lb), it should be derived from the Formula One powerplant in the then-dominating McLaren/Honda cars. When Honda refused, Isuzu Motors, then planning an entry into Formula One, had a 3.5-litre V12 engine being tested in a Lotus chassis. The company was very interested in having the engine fitted into the F1. However, the designers wanted an engine with a proven design and a racing pedigree.

Gordon Murray contacte d’abord Honda, qui motorise alors les McLaren de Formule 1, mais les japonais déclinèrent l’offre de fournir un moteur V12 correspondant à ses besoins.

‘During this time, we were able to visit with Ayrton Senna and Honda’s Tochigi Research Center. The visit related to the fact that at the time, McLaren’s F1 Grand Prix cars were using Honda engines. Although it’s true I had thought it would have been better to put a larger engine, the moment I drove the Honda NSX, all the benchmark cars—Ferrari, Porsche, Lamborghini-I had been using as references in the development of my car vanished from my mind.

Of course the car we would create, the McLaren F1, needed to be faster than the NSX, but the NSX’s ride quality and handling would become our new design target. Being a fan of Honda engines, I later went to Honda’s Tochigi Research Center on two occasions and requested that they consider building for the McLaren F1 a 4.5 litre V10 or V12. I asked, I tried to persuade them, but in the end could not convince them to do it, and the McLaren F1 ended up equipped with a BMW engine.’

- Gordon Murray

Gordon Murray se rapproche donc de Paul Rosche, qu’il connaît bien pour avoir travaillé avec lui du temps de sa période Brabham.

BMW qui venait d’abandonner son projet de M8,une super série 8 dotée d’un V12… BMW cède donc l’exclusivité de ce V12 à McLaren Cars pour sa F1. Ce moteur est tout simplement exceptionnel et présente des caractéristiques formidables : 6 litres de cylindrée, plus de 600 ch !

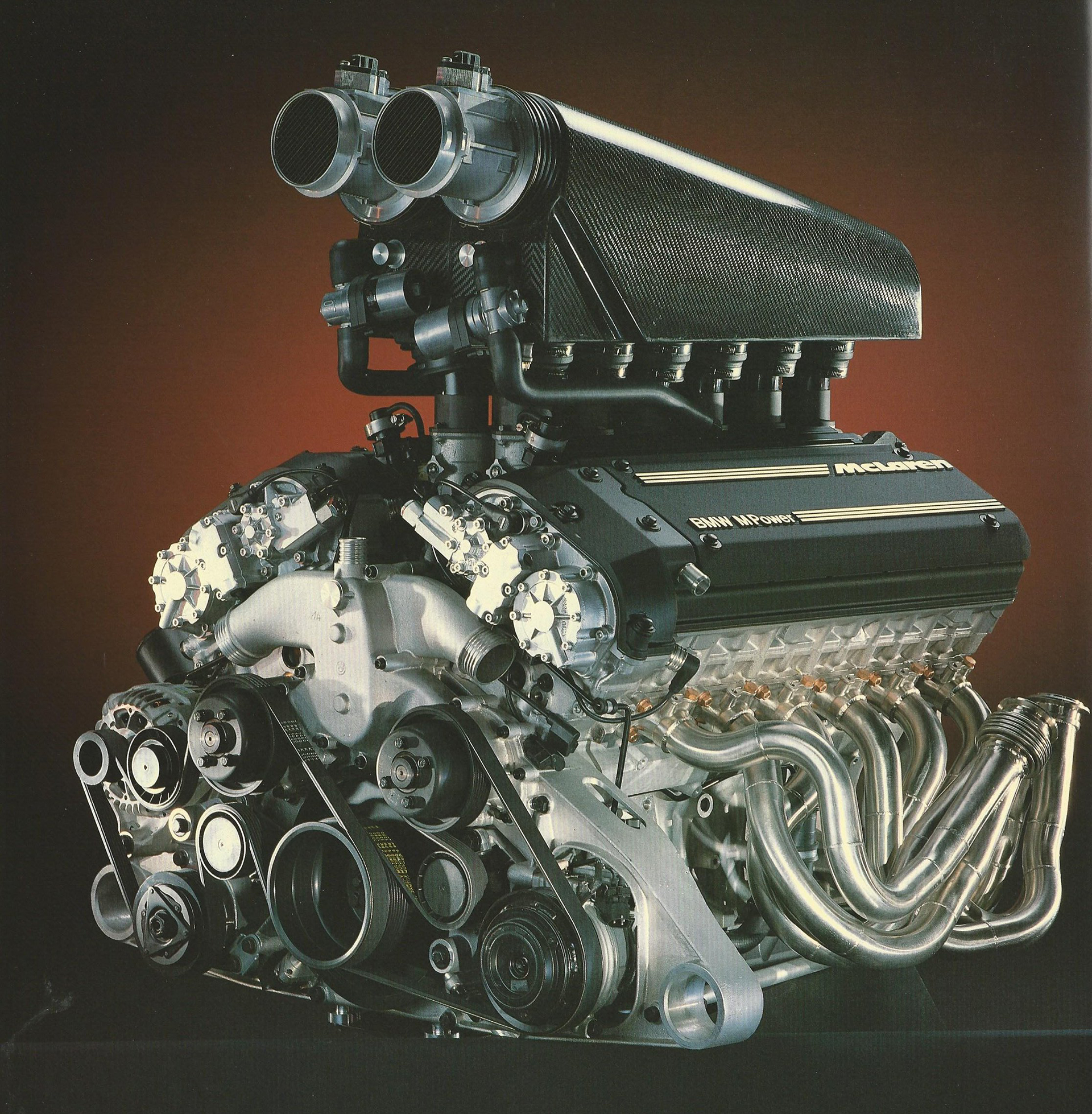

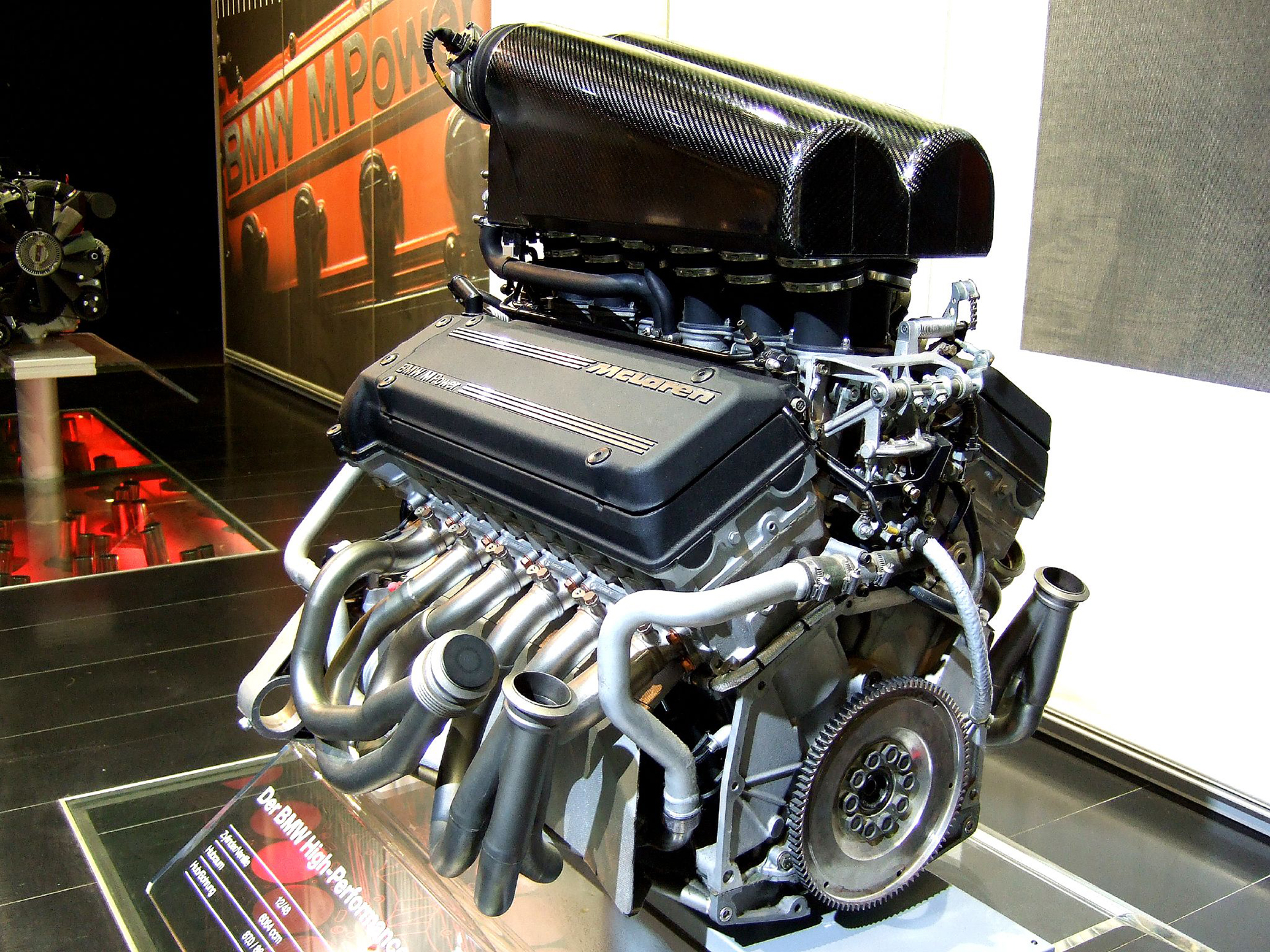

Paul Rosche, motoriste chez BMW, conçoit spécialement à l’attention de la McLaren F1 un V12 de 6,1 litres tout en aluminium, compact et ultramoderne, avec calage variable de la distribution, 12 papillons de gaz individuels et une lubrification par carter sec.

Gordon Murray then approached BMW, which took an interest, and the motorsport division BMW M headed by engine expert Paul Rosche designed and built Murray a 6.1 L (6,064 cc) 60-degree V12 engine called the BMW S70/2.

Ce V12 ‘S70/2′ pèse 266 kilos et le bloc V12 développe 627 ch. C’est donc légèrement plus lourds que voulu mais avec davantage de chevaux de puissance développés.

At 627 PS (461 kW, 618 hp, 627 ch) and 266 kg (586 lb) the BMW engine ended up 14% more powerful and 16 kg (35 lb) heavier than Gordon Murray’s original specifications, with the same block length. It has an aluminium alloy block and heads, with 86 mm (3.4 in) x 87 mm (3.4 in) bore/stroke, quad OverHead Camshafts with variable valve-timing (a relatively new and unproven technology for the time) for maximum flexibility of control over the four valves per cylinder, and a chain drive for the camshafts for maximum reliability.

McLaren F1 – BMW V12 – engine / moteur

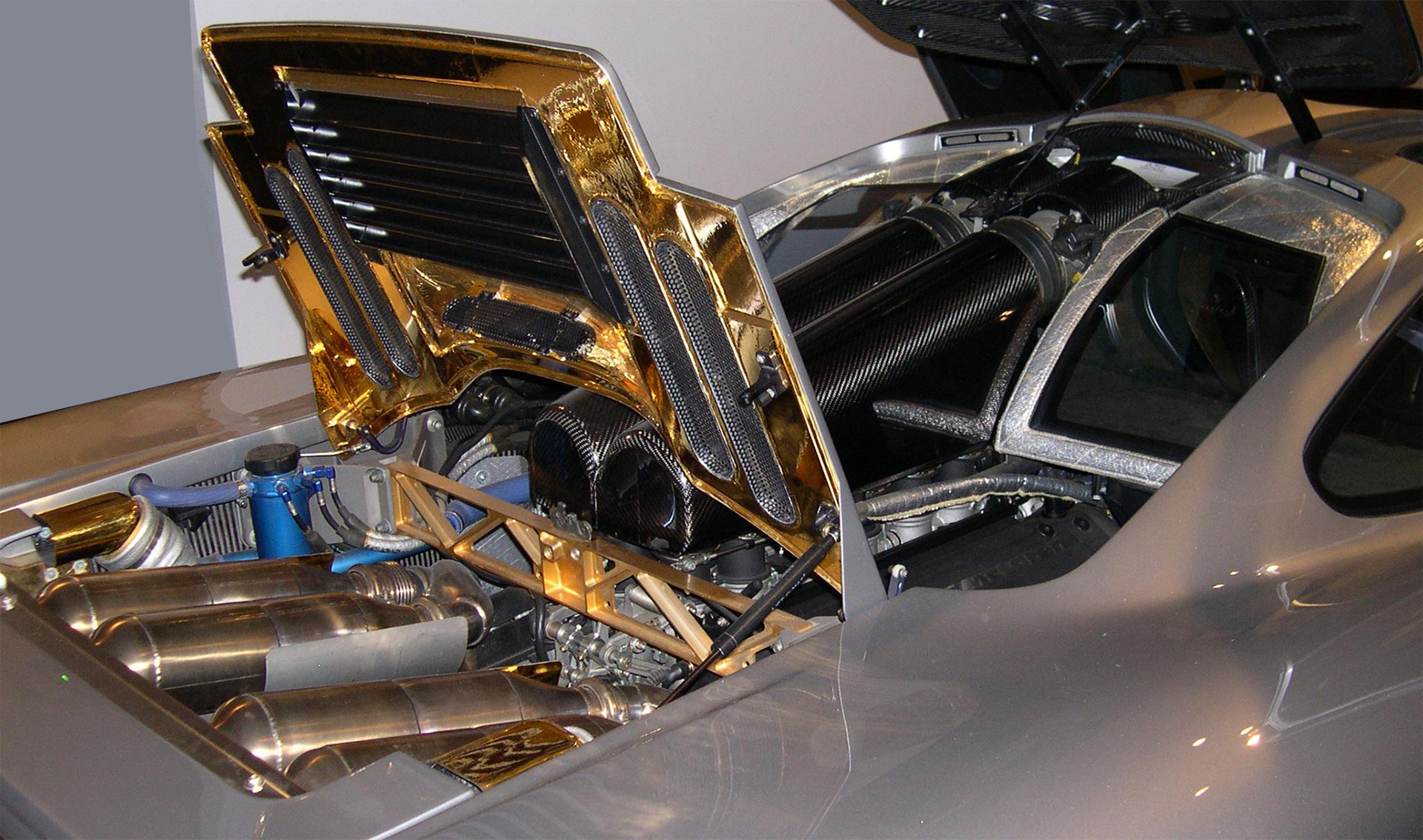

The engine uses a dry sump oil lubrication system. The carbon fibre body panels and monocoque required significant heat insulation in the engine compartment, so Murray’s solution was to line the engine bay with a highly efficient heat-reflector: gold foil. Approximately 16 g (0.8 ounce) of gold was used in each car. The road version used a compression ratio of 11:1 to produce 627 hp (468 kW; 636 PS), at 7400 rpm and torque output of 480 lb·ft (651 N·m) at 5600 rpm.

McLaren F1 – under the hood gold / or sous le capot

The engine has a redline rev limiter set at 7500 rpm. In contrast to raw engine power, a car’s power-to-weight ratio is a better method of quantifying acceleration performance than the peak output of the vehicle’s powerplant.

‘The naturally aspirated 6.1-litre, V12 BMW powerplant generated the highest power output for its size, and delivered over 620bhp. This much power creates a lot of heat. So the engine bay was lined with the best heat reflector available – pure gold.’ - McLaren Cars

Sans limite, c’est ainsi que l’isolation thermique du compartiment moteur est réalisée à l’aide de… feuilles d’or fin, seul matériau offrant un excellent compromis masse/isolation, omme pour les satellites dans l’industrie aérospatial ! Le compartiment moteur est donc thermiquement isolé grâce à un film d’or. Cela représente une valeur de 2 500 livres sterling de l’époque.

McLaren F1 – BMW V12 – engine / moteur – under the hood / sous le capot

La distribution à 2 x 2 ACT* comprend un système de variation continue du diagramme d’ouverture des soupapes d’admission, et le système de gestion, qui fonctionne à partir d’un ordinateur surpuissant, est conçu par TAG Electronics, une filiale du groupe TAG McLaren.

*ACT : arbre à cames en tête

arbre à cames

Un arbre à cames est un dispositif mécanique permettant de synchroniser plusieurs déplacements. Comme son nom l’indique, il s’agit d’un arbre muni de plusieurs cames. Il transforme le mouvement de rotation continu de l’arbre en un mouvement de translation alterné (par exemple d’une soupape), ou bien de rotation alterné (par exemple d’un culbuteur).

Une soupape est un organe mécanique de la distribution des moteurs thermiques à quatre temps permettant l’admission des gaz frais et l’évacuation des gaz brûlés. De manière générale, une soupape d’admission sépare le conduit d’admission de la chambre de combustion et une soupape d’échappement sépare celle-ci du conduit d’échappement.

Un culbuteur est une pièce de mécanique destinée à transmettre un mouvement en changeant la direction et le sens (on parle aussi de basculeur). La transmission se fait par pivotement autour d’un axe.

arbre à cames en tête (ACT) ou SOHC (Single OverHead Camshaft)

L’arbre à cames en tête est une disposition particulière des arbres à cames au-dessus de la culasse.

La culasse est la pièce assurant la fermeture et regroupant certaines fonction, d’un moteur à pistons alternatifs. Elle ferme le haut des cylindres.

Cette disposition particulière des arbres à cames au-dessus de la culasse, est dans le but d’améliorer la commande des soupapes par une diminution drastique des pièces en mouvement.

Pour éviter l’affolement de soupapes à de hauts régimes (environ 4 000 tr/min et plus), il convient en effet de minimiser les pièces soumises à un mouvement alternatif, comme les poussoirs, les tiges de culbuteurs et les culbuteurs eux-mêmes. La suppression de ces pièces éliminant d’autant les jeux mécaniques parasites, la précision de commande des soupapes s’en trouvera améliorée. Pour cela, on place le ou les arbre(s) à cames directement au-dessus des soupapes.

Désormais, la majorité des moteurs d’automobiles sont équipés d’arbre à cames en tête, souvent double, pour actionner les 16 soupapes courantes sur les moteurs modernes à 4 cylindres en ligne. Les moteurs en V utilisant cette technologie occupent plus d’espace dans le compartiment moteur des voitures que les moteurs à soupapes latérales ou à soupapes en tête avec culbuteurs.

Les moteurs à arbre à cames en tête atteignent leur couple et leur puissance maximale à des régimes-moteurs supérieurs à ceux des moteurs à soupape en tête avec culbuteurs. Pour maximiser le rendement, les constructeurs automobiles doivent donc les jumeler à des transmissions ayant un nombre élevé de rapports via une boîtes six vitesses au moins.

Le moteur de la McLaren F1 : BMW S70/2

Le musclé 12 cylindres de 6 litres, est inspiré du 750i issue de la BMW Série 7 type E32 (1986 – 1994) de 300 ch.

Grâce à la technologie 4 soupapes par cylindre, à un vilebrequin en titane et à un embrayage en aluminium, la puissance de ce V12 est portée à plus de 600 ch.

McLaren F1 – BMW V12 – engine / moteur – photo Sweens308

Le V12 BMW est totalement intégré dans la conception de la McLaren F1 puisqu’il est porteur* comme en Formule 1.

*La Lotus 49 est une Formule 1 de l’écurie Team Lotus, conçue par Colin Chapman et Maurice Philippe qui a couru de 1967 à 1970. Conçue à l’origine comme châssis de test pour accueillir le nouveau moteur Cosworth DFV, elle devient la première monoplace de Formule 1 à moteur porteur (elle n’est constituée que d’une demi-coque avant, le moteur Cosworth DFV servant de structure portante à l’arrière) à avoir gagné un Grand Prix.

Le V12 BMW est complété par une boîte six vitesses transversale réalisée sur mesure par la firme américaine Weismann avec des synchros fabriqués par Getrag.

La boîte est située sous le moteur pour permettre d’abaisser le centre de gravité de l’auto et donc optimiser la tenue de route.

The standard McLaren F1 has a transverse 6-speed manual gearbox with an AP carbon triple-plate clutch contained in an aluminium housing. The gearbox is proprietary and was developed by Weismann. The Torsen LSD (Limited Slip Differential) has a 40% lock.

The McLaren F1 has an aluminium flywheel that has only the dimensions and mass absolutely needed to allow the torque from the engine to be transmitted. This is done in order to decrease rotational inertia and increase responsiveness of the system, resulting in faster gear changes and better throttle feedback. This is possible due to the F1 engine lacking secondary vibrational couples and featuring a torsional vibration damper by BMW.

Le poids réduit de la McLaren F1 qui se maintient à la tonne, offre un rapport poids/puissance record pour une auto de route de 1,87 ch par kg. Le moteur V12 BMW de 6,1 litres et ses 610 ch offre une sonorité nettement plus présente et virile que le V12 des série 7 et 8 contemporaines. Vivant et efficace, il propulse la McLaren F1 à des vitesses de 360 km/h ! Le moteur procure des accélérations dantesques avec moins de 20 secondes au kilomètre départ arrêté.

Le son de la McLaren F1 réel commenté par Peter Stevens (in English)

The standard F1 achieves 550 hp/ton (403 kW/tonne), or just 3.6 lb/hp. The cam carriers, covers, oil sump, dry sump, and housings for the camshaft control are made of magnesium castings. The intake control features twelve individual butterfly valves and the exhaust system has four Inconel catalysts with individual Lambda-Sondion controls. The camshafts are continuously variable for increased performance, using a system very closely based on BMW’s VANOS variable timing system for the BMW M3

It is a hydraulically actuated phasing mechanism which retards the inlet cam relative to the exhaust cam at low revs, which reduces the valve overlap and provides for increased idle stability and increased low-speed torque. At higher rpm the valve overlap is increased by computer control to 42 degrees (compare 25 degrees on the M3) for increased airflow into the cylinders and thus increased performance. To allow the fuel to atomise fully, the engine uses two Lucas injectors per cylinder, with the first injector located close to the inlet valve – operating at low engine rpm – while the second is located higher up the inlet tract – operating at higher rpm. The dynamic transition between the two devices is controlled by the engine computer.

Each cylinder has its own miniature ignition coil. The closed-loop fuel injection is sequential. The engine has no knock sensor as the predicted combustion conditions would not cause this to be a problem. The pistons are forged in aluminium. Every cylinder bore has a nikasil coating giving it a high degree of wear resistance.

The engine was given a short development time, causing the BMW design team to use only trusted technology from prior design and implementation experience. The engine does not use titanium valves or connecting rods. Variable intake geometry was considered but rejected on grounds of unnecessary complication.

Le design exterieur de la McLaren F1

McLaren F1 – front light

McLaren F1 – front-face / face-avant – open doors / portes ouvertes

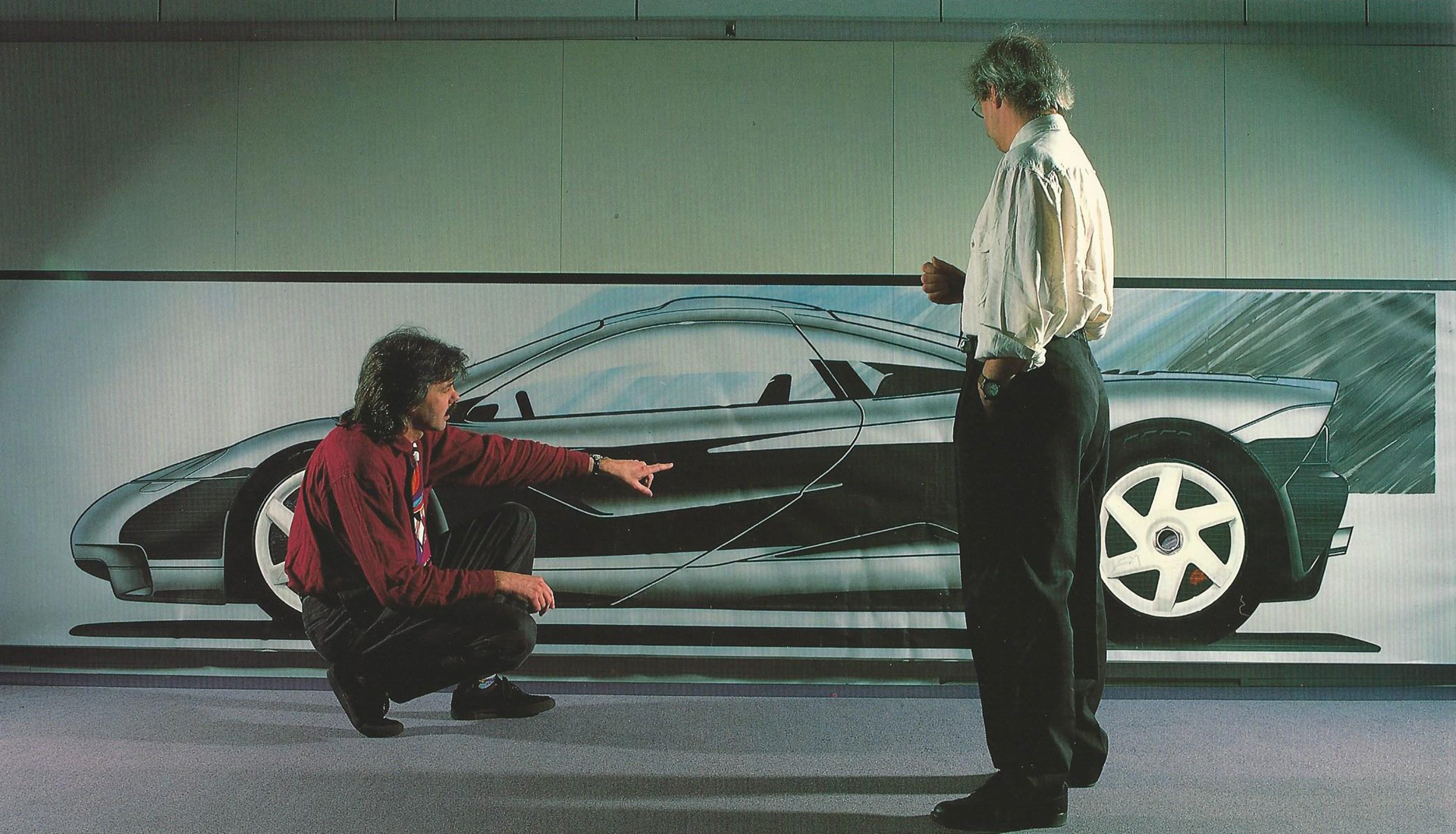

‘To get into the middle seat we did lots of seating bucks; you had to remove a large section of the roof to be able to swing in, and it was a lot easier if you took a lot of the sill away at the bottom, to be able to sit near the middle of the car and then drop yourself in.

I really struggled, and then I saw a styling magazine that had dihedral doors that not only opened a section of the roof, but also cleared the foot-swing area. When we did a mock-up with wire in the workshop, I discovered that you could also take away some of the rocker as well, so that did everything. Then we found a car called the Toyota Sera, and it actually had those doors so we brought it in. The way we did it, removing part of the floor, was original, but it had already been done.’

- Gordon Murray

‘We all agreed that when the doors opened, it should be a little bit of theatre. We saw a little Toyota show car, which had some interesting angled upwards doors, and I’d also worked on Porsche’s 962, and I knew that they stayed closed at 220mph; you need a very strong roof to do that, which we had.

At that time we had a scale wind-tunnel model of the car and we were just thinking of how the door would open, so we made a little welding rod wire-frame shape of the door with a couple of staples in to the body and we quickly found a geometry that worked.’

- Peter Stevens

Gordon Murray explains to Peter Stevens the F1’s Dihedral Door access to its one-plus-two seating.

McLaren F1 – front side-face / profil avant

McLaren F1 – side-face / profil

McLaren F1 – rear side-face / profil arrière

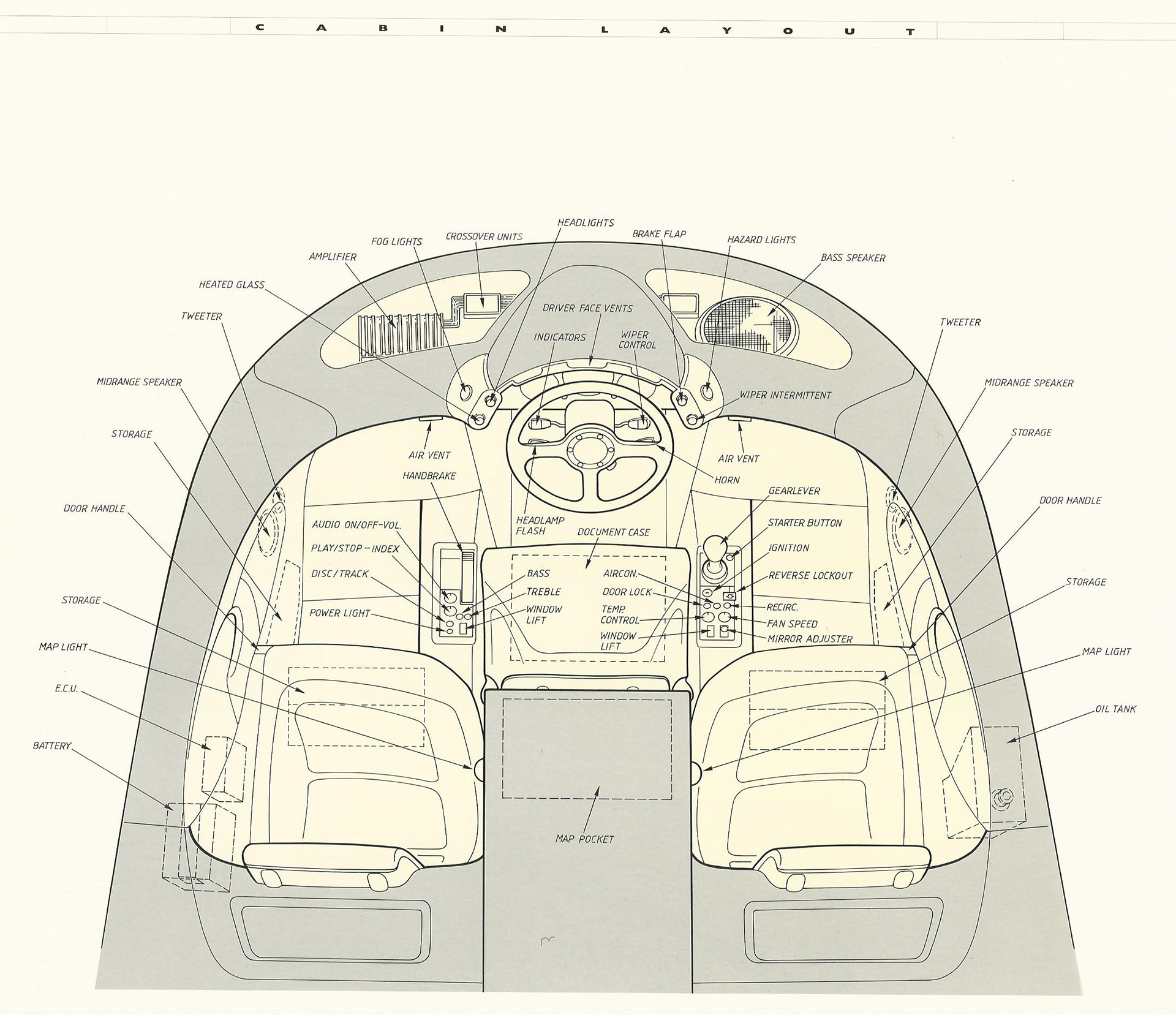

Le design intérieur de la McLaren F1

McLaren F1 – interior / intérieur

Standard equipment on the stock McLaren F1 includes full cabin air conditioning, a rarity on most sports cars and a system design which Murray again credited to the Honda NSX, a car he had owned and driven himself for 7 years without, according to the official F1 website, ever needing to change the AC automatic setting.

Further comfort features included SeKurit electric defrost/demist windscreen and side glass, electric window lifts, remote central locking, Kenwood 10-disc CD stereo system, cabin access release for opening panels, cabin storage compartment, four-lamp high performance headlight system, rear fog and reversing lights, courtesy lights in all compartments, map reading lights and a gold-plated Facom titanium tool kit and first aid kit (both stored in the car).

In addition, tailored, proprietary luggage bags specially designed to fit the vehicle’s carpeted storage compartments, including a tailored golf bag, were standard equipment. Airbags are not present in the car.

All features of the F1 were, according to Gordon Murray, obsessed over including the interior. The metal plates fitted to improve aesthetics of the cockpit are claimed to be 20 thousandths of an inch (0.5 mm) thick to save weight.

The driver’s seat of the McLaren F1 is custom fitted to the specifications desired by the customer for optimal fit and comfort; the seats are handmade from CFRP and covered in light Connolly leather.

By design, the F1 steering column cannot be adjusted; however, prior to production each customer specifies the exact preferred position of the steering wheel and thus the steering column is tailored by default to those owner settings. The same holds true for the pedals, which are not adjustable after the car has left the factory, but are tailored to each specific customer.

McLaren F1 – layout cabin

‘Our no compromise approach to engineering design meant we spent over 3,000 hours making each carbon fibre chassis. The throttle pedal was handcrafted out of six separate pieces of titanium. The instrument panels are handmade, hand painted and each needle is individually machined. This level of precision extended to the driver too – as each cabin was customised to the owner.’ - McLaren Cars

Pendant que Murray cherchait un moteur pour sa supercar, ses collègues de McLaren ne sont pas restés inactifs. Ils ont construit un mulet à base d’Ultima, l’un pour tester la boîte de vitesses à six rapports, les sièges et les freins. La boite de vitesse est ici associée pour l’occasion à un V8 Chevrolet basé sur le moteur 5,7 L de la Corvette.

L’Ultima GTR est une automobile supersportive ou supercar fabriquée par Ultima Sports Ltd basée à Hinckley dans le Leicestershire en Angleterre. Le designer de l’Ultima est Lee Noble.

Un deuxième mulet sera assemblé quelques mois plus tard, et recevra le premier V12 livré par BMW.

Later, a pair of Ultima MK3 kit cars, chassis numbers 12 and 13, naming ‘Albert’ and ‘Edward’, the last two MK3s, were used as « mules » to test various components and concepts before the first cars were built. Number 12 was used to test the gearbox with a 7.4 litre Chevrolet V8, plus various other components such as the seats and the brakes. Number 13 was the test of the V12, plus exhaust and cooling system. When McLaren was done with the cars they destroyed both of them to keep away the specialist magazines and because they did not want the car to be associated with « kit cars »

The car’s safety levels were first proved when during a testing in Namibia in April 1993, a test driver wearing just shorts and a T-shirt hit a rock and rolled the first prototype car several times. The driver managed to escape unscathed. Later in the year, the second prototype (XP2) was specially built for crashtesting and passed with the front wheel arch untouched.

La présentation de la McLaren F1

McLaren F1 – invitation Monaco 1992

L’automobile McLaren est présentée à Monaco le 28 mai 1992, dans une livrée orange, couleur Papaya Orange.

The car was first unveiled at a launch show, 28 May 1992, at The Sporting Club in Monaco. The production version remained the same as the original prototype (XP1) except for the wing mirror which, on the XP1, was mounted at the top of the A-pillar. This car was deemed not road legal as it had no indicators at the front; McLaren was forced to make changes on the car as a result (some cars, including Ralph Lauren’s, were sent back to McLaren and fitted with the prototype mirrors). The original wing mirrors also incorporated a pair of indicators which other car manufacturers would adopt several years later.

Dès le début, les choses sont claires : il s’agira d’une auto ultra-exclusive, pour laquelle aucun sacrifice n’a été refusé : chassis carbone inédit à cette époque, feuille d’or dans le moteur, cockpit habitacle unique avec 3 places de fronts, avec le conducteur au centre avancé vers l’avant.

Le « pilote » est installé en position centrale, comme dans une monoplace, et ses deux passagers sont assis de chaque côté, en retrait. Cela ne facilite pas l’accès à bord, mais permet d’accueillir trois personnes à bord, ainsi que quelques bagages, qui prennent place dans deux coffres situés sur les flancs. A l’intérieur, chaque passager bénéficie ainsi d’une longueur aux jambes appréciable.

La position de conduite centrale donne une vision de la route jusqu’ici inconnue.

L’utilisation massive de carbone et la traque obsessionnelle du moindre gramme superflu, même l’ampli Kenwood a été mis au régime sec, ont permis de maintenir un poids extrêmement réduit : 1 140 kilos environ.

During its pre-production stage, McLaren commissioned Kenwood, the team’s supplier of radio equipment, to create a lightweight car audio system for the car; Kenwood, between 1992 and 1998 used the F1 to promote its products in print advertisements, calendars and brochure covers. Each car’s audio system was especially designed to tailor to an individual’s listening taste, however radio was omitted because Murray never listened to the radio.

Tout était fait pour être le plus léger possible : Le cuir des sièges, le lecteur CD ou la trousse à outils en titane.

Every standard F1 also has a modem which allows customer care to remotely fetch information from the ECU (Engine control unit) of the car in order to assist the customer in the event of a mechanical vehicle failure.

Accessoirement, un modem intégré à la voiture permettait de la relier au support technique de McLaren partout dans le monde. (Imaginez le contexte du Web d’alors, dans les années 1990, à la maison pour accéder à Internet, l’ordinateur devait se connecter via un modem 56k. l’ADSL n’arriva que bien plus tard.)

Et la McLaren F1 obtient d’excellents résultats au crash-tests d’homologation.

Quant au style unique, signé Peter Stevens, il a surtout eu pour tâche d’habiller des lignes dictées par les multiples séances en soufflerie. La McLaren F1 dispose même d’un aileron arrière qui se déploie automatiquement au freinage aux vitesses supérieures à 64 km/h.

Grâce à ses hautes performances, la McLaren F1 reste l’une des voitures de série les plus rapides :

0-48 km/h – 0-30mph : 1,72 s

0-96 km/h – 0-60 mph : 3,15 s

0-161 km/h – 0-100 mph : 5,56 s

0-241 km/h – 0-150 mph : 10,47 s

0-322 km/h – 0-200 mph : 21,43 s

400 m départ arrêté : 10,37 s à 240,15 km/h – 149,22 mph

1 000 m départ arrêté : 18,16 s à 306 km/h – 190,9 mph

Vitesse maximum : 386 km/h – 228,6 mph

La production débute en 1992. Chaque voiture réclame trois mois et demi de travail.

De fait, vu le tarif affiché avec 1 million de dollars, et le contexte économique, la clientèle ne se bouscule guère. La McLaren F1 sera sauvée du naufrage par ses déclinaisons destinées à la compétition.

Pour répondre à la demande de certaines écuries, une version de course McLaren F1 GTR est produite en 1995. Elle est tout spécialement destinée aux courses d’endurance sur des circuits tels qu’Hockenheim, Silverstone, Helsinki et Mugello. Étant dotée d’un appui aérodynamique beaucoup plus important que la version de route, la GTR dispose d’une vitesse maximale presque moindre, mais bénéficie d’une tenue de route exceptionnelle. La gestion moteur, les suspensions, la carrosserie et l’intérieur sont modifiés. Des brides à l’admission d’air limitent la puissance à 607 ch pour satisfaire aux règlements de course.

Ainsi, la McLaren F1, conçue au départ pour un « usage routier » avec de la technologie éprouvé en Formula One, est adaptée pour la compétition endurance sur pistes et fait des merveilles sur les circuits européens.

La McLaren F1 version course, McLaren F1 GTR, remporte une victoire au Mans en 1995, avec Yannick Dalmas, Masanori Sekiya et JJ Lehto. Cette année-là, quatre F1 GTR se classeront aux cinq premières places des 24 Heures du Mans !

McLaren F1 génération 1990

En 1990, c’est le lancement du projet McLaren F1 avec Gordon Murray à la tête du projet, en équipe avec le designer Peters Stevens, et avec la direction de Ron Dennis Team Principal McLaren Formula One team.

En mai 1992, la McLaren F1 est présentée officiellement à Monaco.

En janvier 1993, elle effectue ses premiers tours de piste.

En 1994, la production démarre.

En 1995, la McLaren F1 remporte les 24 Heures du Mans.

En 1996, la version de la McLaren F1 LM dans sa livrée orange, couleur couleur Papaya Orange, est présentée. Elle est allégée avec un moteur V12 BMW amélioré. Cinq exemplaires seront produits. En 1997, présentation de la McLaren F1 GT, dont la carrosserie a été modifiée et allongée pour une meilleure stabilité et une vitesse de pointe accrue. En 1998, la production de la McLaren F1 se termina.

McLaren F1 ‘world’s fastest production road car’

The title of ‘world’s fastest production road car’ was constantly in contention, especially because the term « production car » is not well-defined.

The McLaren F1 has a top speed of 221 mph (356 km/h), restricted by the rev limiter at 7500 rpm. The true top speed of the McLaren F1 was reached in April 1998 by the five-year-old XP5 prototype. Andy Wallace (racer) piloted it down the 9 km (5.6 mi) straight at Volkswagen’s test track in Ehra-Lessien, Germany, setting a new world record of 243 mph (391 km/h) at 8300 rpm.

As Mario Andretti, world champion racing driver, noted in a comparison test, the F1 is fully capable of pulling a seventh gear, thus with a higher gear ratio or a seventh gear the McLaren F1 would probably be able to reach an even greater top speed—something which can also be observed by noticing that the top speed was reached at 7800 rpm while the peak power is reached at 7400 rpm.

Source et images :

McLaren Cars, McLaren Automotive

Partager la publication "McLaren F1 : châssis carbone, design aéro-dynamique, moteur BMW M Power V12. 627 ch."